A Brief History of Straight Razors and How They were Honed

First, this article is not meant to be a comprehensive history of men’s shaving. Many of the conclusions presented in this article are based upon years of experience and study of various straight razor examples. Much of the history is taken from other sources, credit given below. Not everyone agrees with our conclusions.

The Origins of Shaving

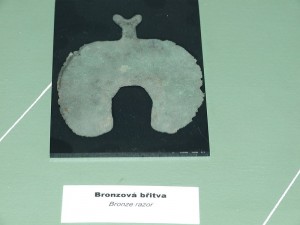

Most historians agree that the history of shaving began when human culture began; which is to say, a long damn time ago. Before the invention of steel, ancient people had the use of shells, which could be used as tweezers, and obsidian, which is incidentally one of the sharpest materials known to man. They also had pumice stones and other rocks they could use to scrape off facial hair. Other materials include sharpened shark’s teeth, clam shells, and flint. Some tribes still use flint razors to this day. Fast forward to the Bronze Age and Roman times and archaeologists have unearthed examples of early razors. These early examples did not have much in common except for a sharp edge, and they were made from bronze.

These early razors were sharpened by either grinding the shells or teeth on other rocks, or in the case of flint and obsidian, through flint knapping. The early bronze and iron razors were sharpened in the same manner as modern knives, albeit without the benefit of special guide rods, diamond stones, and all the luxuries we take for granted today. Back then, ancient peoples had to make do with what they could find; which is to say, the finest “rock” they could find.

These early razors were sharpened by either grinding the shells or teeth on other rocks, or in the case of flint and obsidian, through flint knapping. The early bronze and iron razors were sharpened in the same manner as modern knives, albeit without the benefit of special guide rods, diamond stones, and all the luxuries we take for granted today. Back then, ancient peoples had to make do with what they could find; which is to say, the finest “rock” they could find.

The Rise of Steel

The Rise of Steel

Fast forward some more, and our ancestors discovered iron ore. With the discovery of iron, came the invention of steel. Adding carbon to iron, heating it to a bright glow, then cooling it quickly produces hardened steel; enabling blacksmiths to craft what we know today as steel.

With the invention of steel came newer, sharper, and more durable tools. These new tools included new knives and all manner of sharpened instruments, some peaceful,

some made for war. At this point in history, the razor did not evolve much further from the sharpest tool the local smith could fashion. Such a precise instrument was probably reserved for those with wealth.

Viewing the examples shown, you can see that these early razors were really no more than special knives. Of course, the same can be said today. The honing process for these razors remained unchanged from the process described above, although medieval peoples may have found finer stones with which to achieve finer edges. Yet, there was to be one more invention that made the modern straight razor superior.

The Rise of Sheffield

The Rise of Sheffield

In the mid 1700’s, Sheffield, England was the center of the cutlery industry. Benjamin Huntsman is credited with the invention of the true modern razor. He used a special crucible process to produce steel with superior hardness, able to retain a thinner edge. This time period saw the rise of Sheffield “Silver Steel” called silver steel for its luster and shine, not because it contained any silver. Silver steel was invented by Michael Faraday in the early 1800’s. The shine was actually due to the higher carbon concentration. During this time period through the 19th century, the modern razor scales also came into being.

These razors were sharpened in the same manner as knives. Nothing changed. The geometry of these blades was a true wedge. There was no hollow recess. As such, these early wedges were sharpened free-hand, exactly the same method as used by today’s knife enthusiasts.

As the straight razor continued to evolve, Sheffield began experimenting with hollowing out the razor’s sides. This was most likely due to aesthetic reasons. Not much attention was given into making sure the razor grinding was done evenly, nor was much metal removed. These early attempts at adding a hollow grind were most certainly also honed free hand; just like a knife and the true wedges produced earlier.

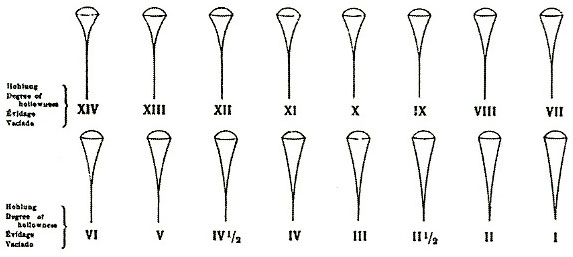

The Modern Razor

Once the razor industry got going, it started making leaps and bounds, eventually creating the straight razor we all know today. 1825 saw the first signs of hollow grinding, but it wouldn’t be fully developed for another sixty years. By 1900, the straight razor had reached its final evolution. The hollow grind reached its zenith with J.A. Henckels offering no less than sixteen different blade profiles! The march continues to this day with modern razor smiths using newer and better tool steels to produce tougher and stronger razors. Yet, the major evolution of the straight razor ceased with the invention of the double wheel grinder and extra hollow blades. The end of the straight razor came with Gillette and their ruthless advertising campaign which put an end to the straight razor and brought on an age of consumerism and a new “throw-away” society.

Once the razor industry got going, it started making leaps and bounds, eventually creating the straight razor we all know today. 1825 saw the first signs of hollow grinding, but it wouldn’t be fully developed for another sixty years. By 1900, the straight razor had reached its final evolution. The hollow grind reached its zenith with J.A. Henckels offering no less than sixteen different blade profiles! The march continues to this day with modern razor smiths using newer and better tool steels to produce tougher and stronger razors. Yet, the major evolution of the straight razor ceased with the invention of the double wheel grinder and extra hollow blades. The end of the straight razor came with Gillette and their ruthless advertising campaign which put an end to the straight razor and brought on an age of consumerism and a new “throw-away” society.

It was the hollow grind that signaled the peak of the straight razor. The hollow grind presented a new and better way to sharpen a razor. No longer did you have to free hand a razor or use a crude and expensive early honing guide. The razor sharpener had only to lay the razor flat against the stone. This required much less skill and produced a vastly superior edge. The advantages are obvious. With a flat honing guide, the bevel angle stays consistent throughout the sharpening process. When you free-hand, there is no guide or reference point to make sure you are using exactly the same angle. But that is not all; the hollow grind offers one more advantage.

It was the hollow grind that signaled the peak of the straight razor. The hollow grind presented a new and better way to sharpen a razor. No longer did you have to free hand a razor or use a crude and expensive early honing guide. The razor sharpener had only to lay the razor flat against the stone. This required much less skill and produced a vastly superior edge. The advantages are obvious. With a flat honing guide, the bevel angle stays consistent throughout the sharpening process. When you free-hand, there is no guide or reference point to make sure you are using exactly the same angle. But that is not all; the hollow grind offers one more advantage.

By honing the razor with the spine to the stone, the bevel angle changes. It becomes more acute. It produces a sharper razor. The smaller the bevel angle, the thinner the actual cutting edge, the sharper the tool. The converse is that the more obtuse the edge, the stronger the edge is and the longer it lasts (assuming you cut the same thing the same number of times). Yet, there is a point of diminishing returns. At some point, you cannot reduce the angle any further without compromising the edge strength and the overall ability of the razor to hold an edge. Steel is not obsidian, it cannot hold an edge too thin. Modern studies reveal that the majority of razors’ range within the 13° to 17° range. This angle can be changed by free-honing the razor or adding tape or using a honing guide.

Sources

http://en.wikipedia.org/wiki/Razor#History

http://www.theinvisibleedge.co.uk/history1.html

http://www.theinvisibleedge.co.uk/history2.html

http://www.theinvisibleedge.co.uk/history3.html

http://straight-edge-razor.com/history-of-the-straight-razor/

Encyclopedia Britannica

Childe, V. Gordon. The Bronze Age. Cambridge University Press MCMXXX.