No, its not really patented, but it sure sounds catchy doesn’t it? The last 5% of the honing process is what everyone argues about. Yet the last 5% is what makes straight razor shaving what it is. Its what makes the shave more comfortable, smoother, easier, and closer. If all our razors were only shave ready, we might as well all switch to DE’s. They’re a lot more convenient, and you don’t have to muck around with finding the right angle and learning to use your left hand (if your truly serious about straight razor shaving). The last 5% make the straight razor sharper and more polished than a DE edge. Yet, the last 5% of the honing process is also where all the confusion, myths, hyperbole, and argument abound. There are literally hundreds of different ways you can finish a straight razor edge. I cannot even begin to list them all in general terms.

In the most general of terms there are three ways to finish an edge: pastes/sprays, natural stones, or synthetic stones. Using a paste or spray causes the edge to become more convex and the edge angle more obtuse. Clearly not desireable. We never use pastes or sprays to finish a razor. The problem with natural stones is that no two are the same. While two natural stones from the same vein may perform similarly, they aren’t exact duplicates. Thus, the hunt for that special natural stone better than the other natural stone you already own. The other problem with natural stones is that there are literally dozens of quarries these were mined from. Some perform well after certain stones, others don’t. Its a confusing morass of infinite combinations. Synthetic stones have the distinct advantage of being exactly alike. Man-made stones will perform exactly as you expect them to. However, this performance is limited to exactly what you expect from the stone. The other problem with synthetic stones is that mixing and matching doesn’t always work very well. Thus, it is generally recommended to stick with one manufacturer. This is because different manufacturers grit ratings vary wildly past 1,000 grit.

What We Do

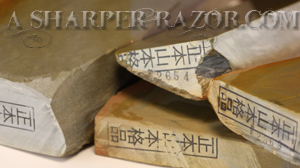

Treating each razor individually means exactly that. Before we even get to the final polishing stage, we check and double check the razor’s sharpness. We make sure the edge is beyond shave ready before we take it to the final stones. This ensures your razor receives the utmost benefit from our final polishing. Then, based upon the razor’s steel composition, grind, customer preferences, and bevel angle we decide upon the best stone in our arsenal to get the best final polish on your razor. If your razor would benefit the most from a scary sharp, but harsh Shapton 30k stone, we use that stone. For scary sharp and pretty smooth, we have a ~40k ceramic stone for that. If the edge would be smoother off of a Nakayama Kiita we use that; if an Asagi would produce a finer edge, we’ll use that stone. If an Escher/Thuringian would work better, we have that too. Some people prefer the edge off a coticule for its smoothness, others a scary sharp edge. People new to straight razors tend to have a much easier time with a smoother, but duller edge. We do that too. Years of experience lets us know the correct slurry levels for all natural stones and some synthetic stones. We can vary the slurry levels to get the edge we want.

Yet, the most important part of this final step is experience. Having sharpened/honed thousands of razors, we know exactly when to stop and how much pressure to apply to get the most out of our stones. Here’s the invisible trap: do too many laps on your finishing stone and your razor’s edge will either roll or break off; ruining all that hard work you’ve put in. Too much pressure and the edge will roll and form a burr. Too little pressure and nothing happens.

The Foundation is Everything

While we’re on the subject of pressure, pressure is extremely important in the steps leading up to the final polishing. No, that is an understatement. The foundation is vital. Not enough pressure on an earlier stone and the actual edge isn’t sharpened. Too much and the bevel is warped. If either of these two happen, the final polishing stones cannot fix the previous error. The stones will only polish the bevel above the edge and will do nothing. This is where those thousands of hours honing comes into play. Getting a razor shave ready is moderately difficult. Getting a razor beyond shave ready takes a mastery of the skill involved.

Finishing the Razor

Having chosen the right medium for your razor, we polish the edge until its just right. Visual inspection using magnification makes sure the bevel is at the correct polish level for the stone we’re using. Then, we do a final test to make sure its where we want it. Then we do a couple of laps on the stone to resharpen the razor to its previous level. This is important because sharpness tests dull the razor. The HHT test doesn’t but only because it only tests the tiniest fraction of the edge and only dulls a hair’s width of the blade incrementally. Its very important to make sure the planned cutting edge is where we want it. So, we test the whole razor.

After the razor passes the final inspection process, we strop the razor for you. This is important because stropping brings out the final shaving edge. We use the finest strops the world has to offer. Real linen and high quality cotton; horsehide and cordovan (cowhide if requested). Then, we oil the blade, put it in a plastic baggie for transport and ship it back to you to enjoy.

We hope you enjoyed this series. Sorry it took so long to write this last part, but as you can see, it is the longest post so far.

I really enjoy your experience and wisdom, refreshing to read someone that believes in telling the whole picture and not leaving you hanging, and to get the rest of the story just purchase their secrets..lol. I have put your site on my bookmarks and will be coming back often to be inspired. I recently started straight shaving, and collecting too. I fell in love with these classic beauty’s and will be even ordering a hand made original too. Sharpening and honing skills is something I truly must acquire and will be faithfully referring here for that next progression. Keep up the great work and telling it like it should be. Sincerly , Rob